%0 Journal Article

%T The Influence of the Carbon Surface on the Rate of Copper Recovery from Slag of the Direct-to-Blister Process

%A Piotr Madej

%A Marian Kucharski

%J Open Access Library Journal

%V 1

%N 8

%P 1-13

%@ 2333-9721

%D 2014

%I Open Access Library

%R 10.4236/oalib.1101057

%X The

study was devoted to the investigation of the influence of the carbon reducer¡¯s

surface on the rate of the copper removal (in the form of a copper-reach alloy,

Cu-Pb-Fe) from the slag produced in the flash direct-to-blister process at the

Glog¨®w smelter in Poland. The

slag used in this work was taken from the direct-to-blister Outokumpu flash

furnace at the smelter in Glog¨®w. Graphite penetrators of different surfaces

were used as the slag reducer, and the experiments were carried out at 1573 K.

It was found that the rate of the de-coppering process of the ¡°Glog¨®w¡± slag

increased with the increase of the reducer¡¯s surface. The rate of the copper reduction from the slag in

the form of Cu-Pb-Fe alloys was identified with the oxygen removal from this

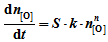

slag and described by the equation: , where:

, where: ¡ªthe number of the oxygen moles which could be

removed from the slag;S¡ªthe surface on which the reduction took place (it was

assumed that it is equal to the penetrator area);k¡ªthe rate constant;n¡ªthe

exponent. It

was found that the

reaction rate ¡°constant¡± as well as the exponent n increased with the increase of

the superficial gas velocity, which was caused by the decrease in the gaps

between the crucibles and the graphite penetrators. Therefore, it can be

concluded that the reduction process was very likely controlled by the

convective mass transfer.

%K Outokumpu Direct-to-Blister Process

%K Slag

%K Kinetics

%U http://www.oalib.com/paper/3126474

¡ªthe number of the oxygen moles which could be

removed from the slag;S¡ªthe surface on which the reduction took place (it was

assumed that it is equal to the penetrator area);k¡ªthe rate constant;n¡ªthe

exponent. It

was found that the

reaction rate ¡°constant¡± as well as the exponent n increased with the increase of

the superficial gas velocity, which was caused by the decrease in the gaps

between the crucibles and the graphite penetrators. Therefore, it can be

concluded that the reduction process was very likely controlled by the

convective mass transfer.

%K Outokumpu Direct-to-Blister Process

%K Slag

%K Kinetics

%U http://www.oalib.com/paper/3126474

, where:

, where: ¡ªthe number of the oxygen moles which could be

removed from the slag;S¡ªthe surface on which the reduction took place (it was

assumed that it is equal to the penetrator area);k¡ªthe rate constant;n¡ªthe

exponent. It

was found that the

reaction rate ¡°constant¡± as well as the exponent n increased with the increase of

the superficial gas velocity, which was caused by the decrease in the gaps

between the crucibles and the graphite penetrators. Therefore, it can be

concluded that the reduction process was very likely controlled by the

convective mass transfer.

%K Outokumpu Direct-to-Blister Process

%K Slag

%K Kinetics

%U http://www.oalib.com/paper/3126474

¡ªthe number of the oxygen moles which could be

removed from the slag;S¡ªthe surface on which the reduction took place (it was

assumed that it is equal to the penetrator area);k¡ªthe rate constant;n¡ªthe

exponent. It

was found that the

reaction rate ¡°constant¡± as well as the exponent n increased with the increase of

the superficial gas velocity, which was caused by the decrease in the gaps

between the crucibles and the graphite penetrators. Therefore, it can be

concluded that the reduction process was very likely controlled by the

convective mass transfer.

%K Outokumpu Direct-to-Blister Process

%K Slag

%K Kinetics

%U http://www.oalib.com/paper/3126474